رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

2018.4.26 Functions of Vertical Roller Mill; The vertical roller mill fulfills four main functions in one compact piece of equipment: Grinding;

Read More

2021.1.1 Raw mix, high grade limestone, sand and iron ore are transported from their bins to raw mills for drying and further fine grinding. The raw mill is either a Ball mill with

Read More

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant. In the cement manufacturing process, raw

Read More

2024.1.1 The raw mill machine functions as a main material grinder in the initial milling process such as limestone, silica stone, clay, and iron sand to become raw mix.

Read More

2020.5.30 The raw mill machine functions as a main material grinder in the initial milling process such as limestone, silica stone, clay, and iron sand to become raw mix.

Read More

2024.4.26 Existing studies mainly focus on the primary functions of equipment, such as the grinding efficiency of ball mills, the thermal decomposition in cyclone preheaters,

Read More

2014.1.14 A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement. Dry raw mills are the normal technology installed

Read More

2016.9.1 Vertical roller mill (VRM) is a large-scale grinding equipment, which is used to grind raw materials from block/granule into powder. Due to harsh production

Read More

2 天之前 Steel mill machinery is one of the most important equipment in steel production. These machines are used in many different stages of steel production, from processing raw materials to shaping steel sheets,

Read More

2023.8.1 The characteristics of Palm Oil Mill Effluent (POME) is a crucial factor affecting the yield and quality of biogas produced from anaerobic digestion. Hence, it is

Read More

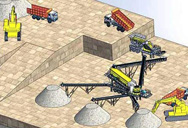

2019.9.27 Cement crusher is the main equipment of this step. The raw materials are fed into cement crusher by vibratory feeder; the breaking material is transported by the belt conveyor to the impact crusher for

Read More

Get Pricefunction of equipment of raw mill,Function Of Table Feeder In Cement Mill.Rawmill wikipedia a raw mill is the equipment used to grind raw materials into quotrawmixquot during the manufacture of cement rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw ...

Read More

Part Three: Raw Mill. Process of Raw Mill The proportioned raw material is feed first to a grinding mill. In the mill, particles ground in to very fine sizes. In the grinding unit, drying, grinding and mixing takes place

Read More

2023.12.1 1. Material Crushing: The primary function of the corn grinder is to crush a variety of raw materials into particles suitable for different purposes. Utilizing a hammering mechanism, this equipment effectively crushes tough materials like corn stalks, corn cobs, grass, and straw, ensuring the particle size meets specific requirements. 2.

Read More

Type of mill: Ball and tube mills. Vertical Roller Mills (VRM). Horizontal roller mill (Roll Press) Roller press with Ball mill. Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two ...

Read More

function of equipment of raw mill - lemasderoquegrise. Rawmill - Wikipedia. A raw mill is the equipment used to grind raw materials into "rawmix" Charlar en Línea; Effectivity analysis of raw mill 4R1 and 4R2 using Overall . 2019.5.1 The result of this research is the effectivity of the Raw Mill 4R1 and 4R2 that is equal to 60% and 72%.

Read More

3 天之前 APPLICATION CRITICALITY. The rotary kiln is the heart of a cement manufacturing plant. Cement kilns have all chemical ingredients. These. ingredients are at a broad range of gas temperatures from 100° to 1650°C. At CCCL, the kiln gases are at around 900 deg C. Pyroprocessing consists of five stages.

Read More

This process can be used only for a cement raw mix with narrow input variations (about ± 1 %). In this case, prehomogenizing of the raw material components is a prerequisite. The raw mix is conveyed into a distribution basin. This container is supplied with radially arranged pneumatic trough conveyors (distribution spider).

Read More

Vibration velocity at mill gearbox [mm/s]. Power consumption of mill motor with span [kW or alternatively A] Power consumption of system fan [kW] Mill outlet temperature [°C]. Tension pressure [bar] Classifier speed [rpm] Fineness of product [Residue on 90µm sieve , Blain, moisture] Amount of water injection [l/h]

Read More

2016.9.1 Vertical roller mill (VRM) is a large-scale grinding equipment, which is used to grind raw materials from block/granule into powder. Due to harsh production environment and inconsistent raw ...

Read More

A sufficient air flow will result in a mill differential pressure of> 5mbar. The duration of heating should be at least until the temperatures after mill and after bag filter reach 85° C. After long shut down periods (>10h)

Read More

2024.1.1 IOP Conference Series: Materials Science and Engineering PAPER OPEN ACCESS Analysis of Raw Mill Machines Maintenance in Cement Industry To cite this article: R M Sari et al 2020 IOP Conf. Ser.: Mater.

Read More

Production Capacity: 5-200tph. Feeding Size: ≤110mm. get price! Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plant. Vertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one.

Read More

function of vertical rollwe mill in cement. Vertical roller mill - Wikipedia, the free encyclopedia. Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in ...

Read More

2021.1.1 The raw mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier. The hot gases from the pre heater enter the mill and are used for drying material in the mills. ... Machine / Equipment Used Purpose of Process; 1: ... One single machine embodies all functions, i.e. simultaneous drying, grinding, ...

Read More

2 天之前 Steel mill machinery is one of the most important equipment in steel production. These machines are used in many different stages of steel production, from processing raw materials to shaping steel sheets, plates, and bars. Steel mill machinery performs various tasks with high technological features.

Read More

2024.2.23 The raw materials are fed into the mill and then crushed by multiple grinding wheels or rollers. The resulting powder is used for cement production. The operation of the cement raw mill is a critical step in cement production. By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement

Read More

2016.1.20 A mixed material, having a humidity rate of 2.82%, moves from the material silos into the raw mill. The kiln exit gases are conditioned in the gas conditioning tower to leave at 528.15 K, for pre-heating and drying the feed to the raw mill. In the mill, the mixed and dried materials exit as raw meal with a humidity rate of 0.48%, after grinding.

Read More

2022.12.19 A raw mill is a key piece of equipment used in a cement plant to grind raw materials into a fine powder. It works by crushing and grinding materials such as limestone, clay, and iron ore into a ...

Read More

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.. The

Read More

2006.11.21 1 Introduction. The objective of a rice milling system is to remove the husk and the bran layers from paddy rice to produce whole white rice kernels that are sufficiently milled, free of impurities and contain a minimum number of broken kernels. The milling yield and quality of rice is dependent on the quality of the paddy, the milling ...

Read More

1.Axial/radial runout. 2.Alignment of the drive trains. 3.Uneven power splitting. 4.Centre distances variable. 5.Face load distribution. 6.Sealing of the girth gear. 7.Girth gear is through hardened only, fatigue strength is

Read More

2016.11.3 Milling is a step that happens during the post production of rice. Paddy cannot be consumed in its raw form and has to undergo certain procedures in order to be fit for consumption. The purpose of ...

Read More

2018.9.10 the raw mill studied using Aspen plus simulator modelling technique was found to be 21.4%. It was. found that the difference in exergy efficiencies of the simulation results of the three ...

Read More

2024.6.13 12TH AUSIMM MILL OPERATORS’ CONFERENCE / TOWNSVILLE, QLD, 1–3 SEPTEMBER 2014 227 INTRODUCTION Comminution is the leading consumer of energy and is one of the highest expenses in a mineral concentrator (Coalition for Eco-Efficient Comminution (CEEC), 2013). Worldwide mining industry equipment efficiencies

Read More

2017.8.12 The latest information about our over-seas companies is available on our homepage loesche. Loesche GmbH Hansaallee 243 40549 Düsseldorf, Germany Tel. +49 - 211 - 53 53 - 0 Fax +49 - 211 - 53 53 - 500. E-mail: loesche@loesche loesche.

Read More

There are various types of screening equipment, including pressure screens, gravity screens, and centrifugal screens. Applications: Screening equipment is used in the screening process, which removes unwanted materials from the pulp and improves the cleanliness and uniformity of the pulp fibers. Maintenance Tips: Regular cleaning and

Read More

Get Solution Price Right Now! leave your message here, we'll send you an Email immediately. * *

Read More

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal

Read More

Conclusion. In conclusion, the application of vertical roller mill technology in the cement industry has revolutionized the way cement is produced. VRMs are more energy-efficient, eco-friendly, and produce a more consistent product compared to traditional grinding mills. They are also more suitable for use in urban areas due to their lower ...

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.