رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

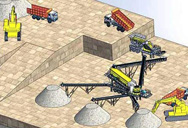

2024.7.10 Properly designed limestone crushing plant supported by best practices deliver consistent, high-quality crushed outputs catering to varied commercial needs. Enhancing Limestone Crushing Efficiency with Portable Crusher. Portable Crusher Plant

Read More

2023.2.28 Efficient and effective crushing operations in a stone crusher plant can be ensured by optimizing equipment selection and configuration, implementing effective

Read More

2024.7.11 The limestone aggregate crusher plant is a production line for aggregate and artificial sand making plant. It has the characteristics of high degree of automation,

Read More

2023.1.19 The proposed limestone crusher is Impact Crusher, it can crush the material from 1m to –25 mm size. The crushed limestone will be sent by a belt conveyor

Read More

2024.1.11 The limestone sand-making plant process mainly includes three stages: coarse crushing, fine crushing, and sand making. The finished sand and gravel

Read More

2024.7.11 The limestone crushing process involves several stages, each with specific machinery and equipment. The typical limestone crushing process is Primary Crushing ->

Read More

2023.1.19 Design the limestone crushing process, and briefly introduce the process designed by SBM experts. Second, limestone crushing processing equipment. SBM's

Read More

2019.11.4 The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc. JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energy-saving performance.

Read More

2016.2.24 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production

Read More

Abstract: Typical cement processing plants process raw material, referred to as ore which mainly consist of limestone, to produce cement products. The ore is collected by large

Read More

5 天之前 Stone Crushing Plant Features: CFTC provides more professional and practical solution on building your 20-3000 tph hard stone or soft stone crushing plant, including solution on system layout, optimal equipment configuration, high-quality equipment, equipment installation, technical support, after-sale service, etc.Our stone crusher plant

Read More

2021.11.15 Cases of Limestone Crushing Plant. Capacity: 100t /h. Feed size: ≤600mm. Processing materials: lime, limestone. Reviews: large processing capacity, smooth operation. Limestone crushing plant

Read More

For that lime stone crushing plant designed to reduce large rocks into smaller rocks, gravel, or rock dust. Stone Crushers plant may be used to reduce the size, or change the form, of waste materials so they can be

Read More

AIMIX provides crushing plants with many capacities. 50 tph stone crusher plant price starts from 60,000 USD, 100 tph stone crusher plant price starts from 100,000~140,000USD, 200 tph stone crusher plant price starts from USD 230,000. The above stone crusher plant price list is just a range because the price can be influence by some other factors.

Read More

Limestone Crushing Train Processing Plant; Have a Question? Ask our expert. Speak your question. Please enter your question. Stone Crusher Plant, Capacity: 200-400 T/H ₹ 50,00,000 Get Latest Price . Capacity: 200-400 t/h. Power (kW) 400. Voltage (V) 220-440 V. Automation Grade: Automatic. Phase: 3 Phase.

Read More

2023.2.24 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects. In this comprehensive guide, we explore the different types of crushed stone machines, their components, and how to operate them safely and efficiently. We

Read More

This plant has been successfully applied in the crushing processing of limestone, basalt, granite, pebble, and other rocks. The product quality completely reaches the GB14685-2001 standard, which can be regarded as aggregate for high-grade highway, railway, water conservancy, concrete mixing plant, and other industries.

Read More

2020.12.11 Recently, AGICO CEMENT has built a cement crushing plant project in Anhui. This is a limestone crushing plant, the main component of limestone is calcium carbonate (CaCO3), Mohr hardness is 3, rich resources, raw ore grade can generally meet the requirements of various industrial departments, the limestone crushing plant

Read More

2024.7.10 Working Principle: Jaw crusher use compressive force for crushing. The limestone is compressed between a fixed jaw plate and a movable jaw plate. This makes them robust for abrasive limestone crushing. Feed Size: Jaw crusher can accept large limestone lumps or rocks as feed sizes ranging from 1000-1200mm depending on the

Read More

Royal Engineering is one of the leading Manufacturers of Crushing Plant across the world. Since 1995 we have been leading manufacturer and supplier for Crushing Plant, Crusher Machine, Jaw Crusher, Grinding, Screening, Conveying Equipment, also Mineral processing plant equipments for the field of Mines, Quarry, Minerals, Chemicals, Pharmaceuticals,

Read More

2023.9.14 Crushing rocks is a common everyday activity for various uses, but achieving the desired size and achieving it with efficiency can be challenging. That’s where Crushers come into play. ... LT is the largest Limestone Crushing plant supplier. Our crushers dominate the market, covering major cement plants across India. Additionally,

Read More

Limestone Crushing Plant ₹ 1,45,00,000 Get Latest Price . Avail from us high functionality Limestone Crushing Plant that is ideal for fixed as well as mobile applications. This crushing plant provides an ideal option to crush

Read More

2016.2.24 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to

Read More

Bohol Limestone Plant; News Release; Contact Us; BOHOL LIMESTONE Limestone. May 31st, 2022 01:10 pm pmsc_admin. Products Limestone. PMSC's chemical-grade Bohol Limestone is a very stable polymorph of Calcium Carbonate with high-concentration of Lime, hence has very minimal impurities and is chemically stable, and can cater to a wide

Read More

250 TPH 3 Stage Crushing and Screening Sand Plant “We are in the crushing business for 26 years and have eight plants in India. Our association with Propel goes back to 2010 and they are one of the best stone crushing machinery manufacturer in India. I rate them in the topmost slot in terms of product performance, service and spare parts.

Read More

2022.2.16 Debris Crushing Lime Production. – Supply The Crusher With Stones From The Field And Crush Them Into Lime For Fertilizer Spreading Or Sell It For A Tidy Profit! – Price: 15,000 – Max Capacity: 250.000 – Production Value: 1000l Stone – 4000l Lime – Cycles Per Hour: 20 – Costs: 5.00 Per Hour – Lights So You Can Use It At Night

Read More

2024.7.11 Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite. It is a kind of stone widely found in nature. Limestone can be directly processed into stone using crushing equipment and fired into quicklime. Quicklime absorbs moisture or adds water to become hydrated lime.

Read More

5 天之前 Crushing Plant Flowsheet Design-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone crusher ...

Read More

3 天之前 Jaw crushers have a robust structure and are ideal for primary crushing by applying compressive forces to break large limestone into smaller particles. The capacity range is all in the range of 1-800t/h. However, it should be noted that the feed size range of APJ-E series small size jaw crusher limestone for sale is from 130mm to 1000mm.

Read More

2021.6.24 Lokotrack primary mobile crushing plant to fur-ther processing stages. They are able to follow the primary unit as it moves along the quarry face, replacing costly dump truck haulage. Plant automation systems – monitor and control all crushing, screening, storing and con-veying with real-time accuracy. Maintain maxi-

Read More

2023.2.28 The workflow of a stone crusher plant involves several steps, including the feeding, crushing, screening, and conveying of materials. The materials are fed into the primary crusher by the vibrating feeder, where they are crushed into smaller pieces. The smaller pieces are then sent to the vibrating screen for separation.

Read More

Torsa is the biggest crushing screening plants in India who specialize in producing stone crushers, cone crushers and automatic crushing plants. info@torsa Toll Free : 1800 121 5696 Find Your Product

Read More

Limestone crusher plant is kind of special stone processing line for crushing hard mineral. To meet the production requirements, it can take coarse or fine crush for the limestone to produce stones of all sizes. This is beneficial to the deep processing of limestone in the later stage. Large amount of limestone is used as building material and ...

Read More

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

Read More

Stone Crusher Plant, Vertical Shaft Impactor Single Toggle Jaw Crusher Manufacturer offered by Rockcut Infra Private Limited from Hyderabad, Telangana, India Rockcut Infra Private Limited Jeedimetla, Hyderabad, Telangana GST No. 36AAKCR0942B1ZN

Read More

2023.2.23 Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges. Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability

Read More

2023.2.24 Generally, the estimated cost to set up a stone crushing plant ranges from $10,000 to $1,000,000. The capital needed to set up a stone crusher plant generally depends on the following factors: Land acquisition: The cost of acquiring land varies depending on the location and size of the land. In some areas, the cost of land can be

Read More

2024.3.1 In certain stone crushing plants, the production of sand is a key component. Sand making machines , also known as vertical shaft impactors, are designed to produce high-quality artificial sand by finely crushing and shaping aggregate materials (such as rocks, granite, limestone, and asphalt concrete).

Read More

2019.11.11 Limestone: A sedimentary rock and the most commonly used rock type for crushed stone in the United States. One of the most versatile rocks for construction, limestone is able to be crushed easily, making it a primary rock used in ready-mix concrete, road construction, and railroads. It is widely available in quarries across the country.

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.